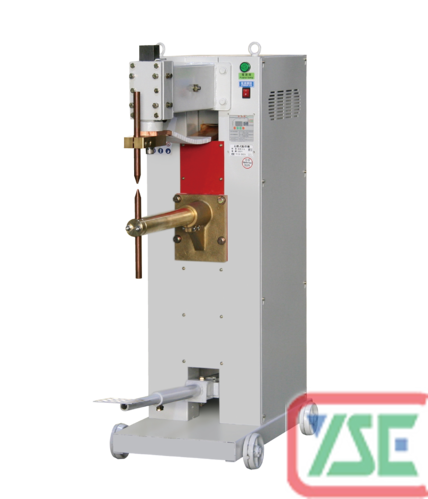

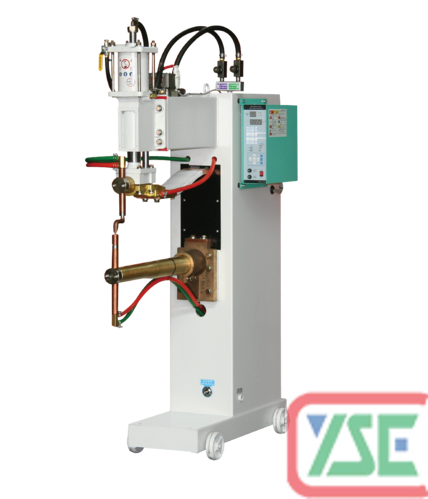

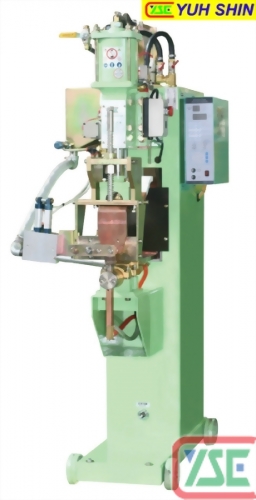

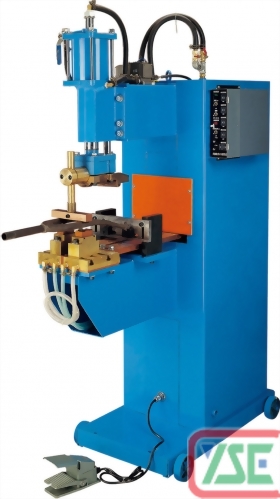

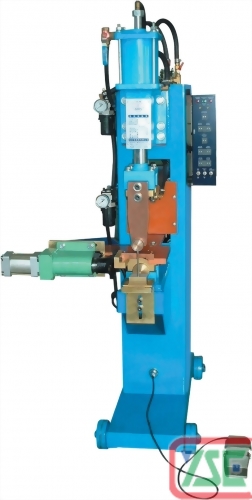

Spot & Projection Welding Machines

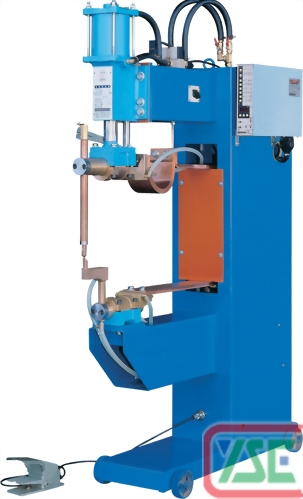

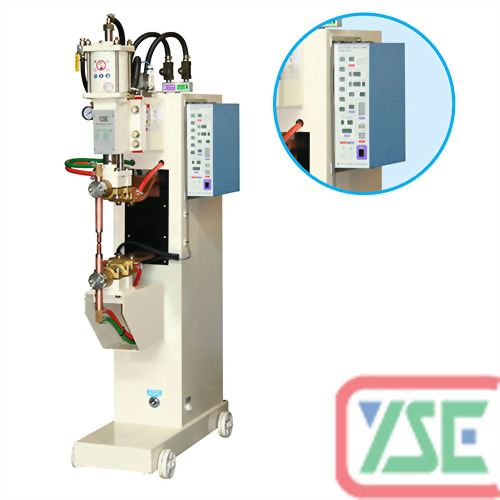

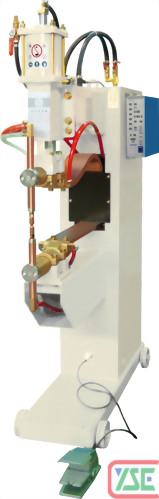

Resistance welding machines, categorized into five main types: AC, DC, capacitor discharge, inverter, and transistor. Each type offers distinct advantages, disadvantages, and value, making the selection process crucial. The most effective approach is to choose a welding machine based on specific needs, the suitability for your workpieces, and experimental results. The common type of resistance welders includes spot welding, projection welding, seam welding, butt welding and flash welding.

It's important to note that resistance welders typically use a filler-free welding method, unlike CO2 and Argon welders which require filler material. The electrode material, shape, and design are particularly important for weld quality, as they are consumable components. Utilizing alloy copper electrodes with low-voltage and high-current of resistance welders allow the metal to reach high temperatures instantly, fulfilling the welding requirements. We also offer micro and precision models for smaller workpieces that require high welding precision.

By communicating with customers about their welding needs, we, Yuh Shin propose suitable solutions and machine models to solve the welding needs of workpieces. Spot welders are widely used in the automotive industry for sheet metal and various interior components/parts whether they are large or small.

Resistance spot welding is a thermo-electric joining process that welds two or more thin sheets of metal together without filler material. This is achieved by using copper alloy electrodes to apply pressure and pass a high electrical current through the sheets. This fast and low-voltage process is commonly used in related sheet metal manufacturing industries for overlap joints, especially in the automotive field.

Differences Between Spot Welding And Projection Welding

1. Principle

Spot Welding

-

The weld is formed by pressing two flat sheets together between copper electrodes.

-

Current flows through the contact area and heat is generated by electrical resistance.

-

The weld nugget forms at the point where the sheets touch.

Projection Welding

-

One or both workpieces have raised projections.

-

Current is concentrated at these projections.

-

When pressure and current are applied, the projections collapse and form one or more weld nuggets.

Spot Welding:

Automotive Body And Chassis, Electrical and Electronics, Aerospace, Bicycle, Household Appliances, Sheet Metal Parts Manufacturing, Metal Furniture And Construction, Kitchen Furniture And Appliances, Battery Packs, Wire Mesh Products, Wire Harness Assembly And other various sheet metal fabrication industries.

Projection Welding:

- Welding nuts, bolts, and studs to sheet

- Cross-wire welding (grids, meshes)

- Parts requiring multiple precise welds at once

3. Surface Appearance and Electrode Life

Spot Welding

Leaves visible electrode marks.

Electrode tips wear faster due to direct contact and high current density.

Projection Welding

Minimal marking on outer surfaces.

Longer electrode life because current is focused at projections, not at the electrode face.

In short, spot welding is simpler and widely used for general sheet-metal joining, while projection welding offers higher precision, the ability to make multiple welds in one operation, and is ideal for attaching fasteners and complex assemblies.