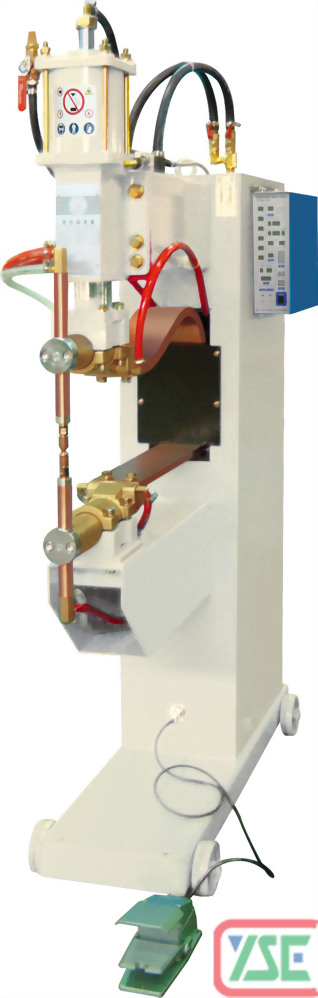

35~50KVA Spot Welders

1.Temperature protection switch to prevent Thyristor from overheating and breakdown

2.Digital welding microcomputer Timer, ensures accuracy of welding time

3.End Output Signal can be sent to the other peripheral welding devices

4.Japanese brand Timer TETRA-K is also available, and it provides constant welding current

5.Applications include automotive, motorcycle sheet metal parts, metal cabinet, electrical panels, metal enclosures, stamping parts and many others. Also available in single or multi-point spot weld

| Type | 定格容量 | 一次電壓 | 週波數 | 最大電流(溶接時) | 最大入力(溶接時) | 容許使用率 | 喉部尺寸 | 電極棒(座) | 電極頭 | 最大加壓力 | 冷卻水量 | 重量 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Capacity | Input Voltage | Frequency | Max. Welding Current | Max. Welding Input | Duty Cycle | Throat Size GapxDepth | Electrode Bar(Seat) | Electrode Tip | Max. Pressure Force | Cooling Water | Weight | |||

| KVA | V | Hz | A | KVA | % | mm | φ(mm) | φ | kg | L/Min | kg | |||

|

Spot Welders 單點式熔接機 |

YS-354-5D | 35 | 220 | 50/60 | 15000 | 79/87 | 7 |

|

25 | 16 | 500 | 6 | 275 | |

| YS-A356-5D | 35 | 220 | 50/60 | 14000 | 77/86 | 7 |

|

25 | 16 | 500 | 6 | 280 | ||

| YS-A504-5D | 50 | 220 | 50/60 | 18000 | 99/110 | 7 |

|

25 | 16 | 500 | 6 | 295 | ||

| YS-A506-5D | 50 | 220 | 50/60 | 16000 | 88/98 | 7 |

|

25 | 16 | 500 | 6 | 300 | ||

| YS-A508-5D | 50 | 220 | 50/60 | 14000 | 81/91 | 7 | 200*800 | 25 | 16 | 500 | 6 | 310 | ||

| YS-A754-10D | 75 | 220 | 50/60 | 22500 | 123/143 | 7 | 200*400 | 25 | 19 | 1000 | 8 | 460 | ||

|

Spot - Projection Welders 單點、浮凸 兩用式熔接機 |

YS-A354-5T | 35 | 220 | 50/60 | 18000 | 94/104 | 7 | 180*400 | 25 | 16 | 500 | 6 | 283 | |

| YS-A504-5T | 50 | 220 | 50/60 | 23000 | 133/149 | 7 | 180*400 | 25 | 16 | 500 | 8 | 305 | ||

| YS-A754-10T | 75 | 220 | 50/60 | 29000 | 220/254 | 7 | 180*400 | 32 | 19 | 1000 | 8 | 470 | ||

| YS-A1004-10T | 100 | 220 | 50/60 | 32000 | 296/350 | 7 | 180*400 | 32 | 19 | 1000 | 8 | 490 | ||

|

Projection Welders 浮凸專用熔接機 |

YS-A503-10T | 50 | 220 | 50/60 | 28000 | 181/205 | 7 | 200*300 | 1000 | 8 | 305 | |||

| YS-A753-10T | 75 | 220 | 50/60 | 33000 | 296/350 | 7 | 200*300 | 1000 | 8 | 470 | ||||

| YS-A1003-15T | 100 | 220 | 50/60 | 35000 | 296/350 | 7 | 200*300 | 1500 | 8 | 490 | ||||

| YS-A1503-15T | 150 | 220 | 50/60 | 43000 | 411/450 | 7 | 200*300 | 1500 | 10 | 600 | ||||

| YS-A2003-30T | 200 | 440 | 50/60 | 50000 | 550/611 | 7 | 200*300 | 3000 | 10 | 650 | ||||

1. Custom-Built models are welcome, simply send us the workpiece specification and welding requirement. Our engineers are available to work with you to customize welders that meet your specific application requirements.

2. Specifications are subject to change without prior notice due to constant improvements.