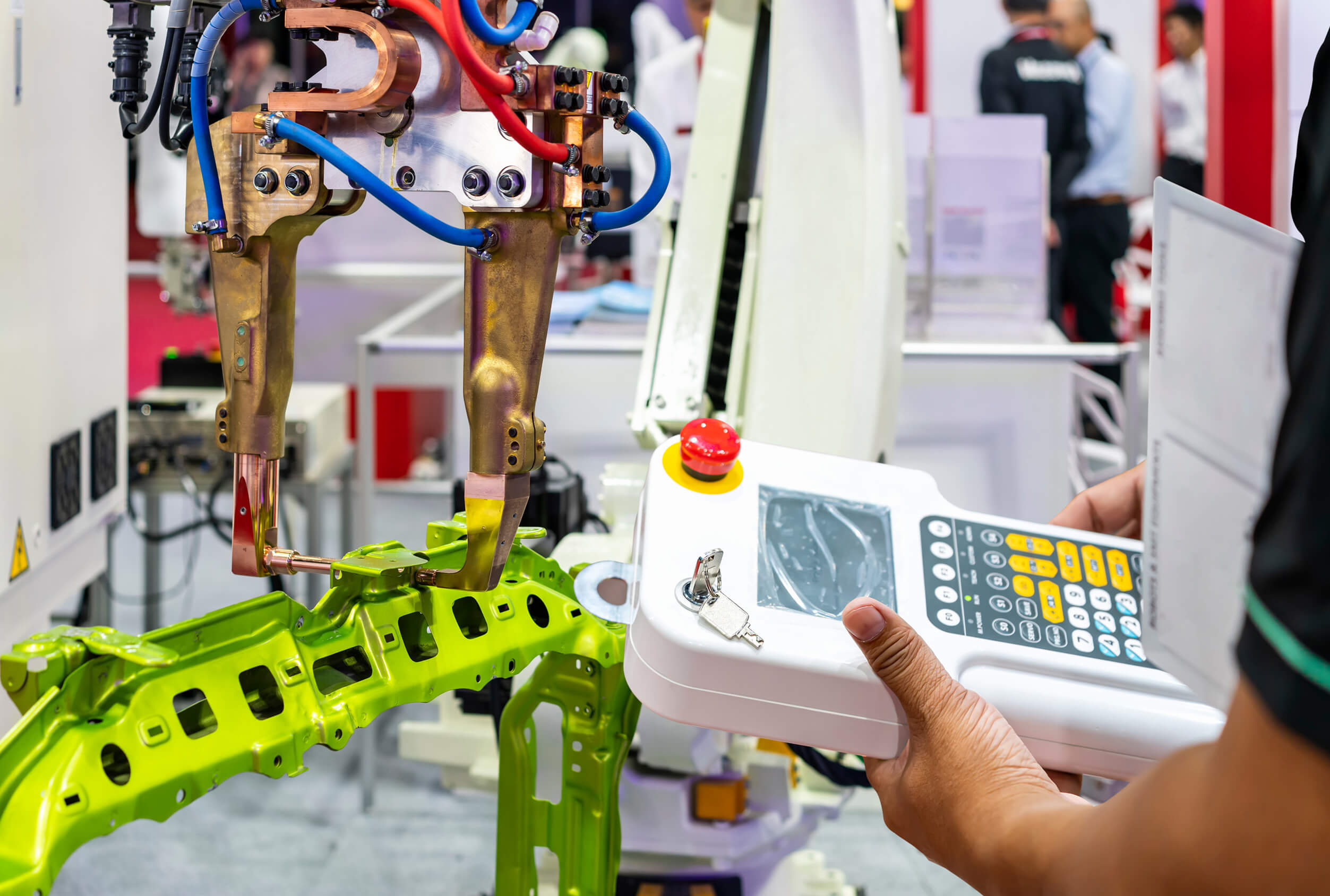

The Key factors for a successful resistance welding Process?

1)Welding Current: Directly proportional to heat generation, the current impacts weld nugget size. Excessive current can cause expulsions and electrode damage.

2)Welding Time: The duration of current flow is crucial for heat transfer. Both a minimum and a correct time are necessary for a good weld.

3)Welding Force: Proper pressure compresses workpieces, ensuring smooth current flow and good contact. Incorrect force leads to poor weld quality.

4)Electrode Shape: It significantly influences resistance welding quality. It dictates current and pressure distribution, which in turn impacts weld strength, consistency, and appearance.

2025-11-12