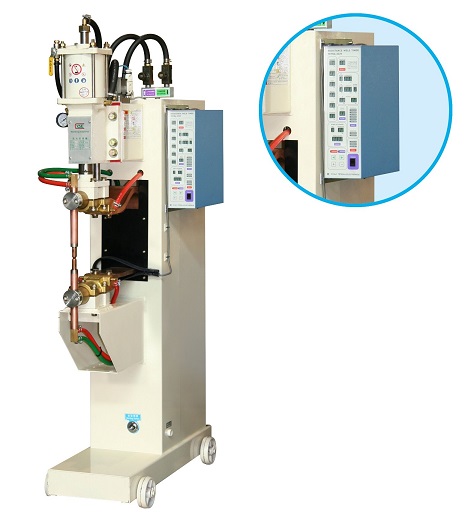

Characteristics of various welding power supplies

1)AC welding power supply: AC welding, characterized by its simple power source that controls the conduction angle of AC current, is generally best suited for easily weldable ferrous materials. However, it has relatively poor thermal efficiency, which can lead to a larger heat-affected zone on the workpiece. For this reason, it is not ideal for high-precision welding applications.

2)DC Inverter welding supply: No current stop time, and it can continuously provide heat energy, with advantages such as high thermal efficiency, short welding time, small heat impact, and suppressed power loss. High-speed loop control can prevent spatter, stabilize welding quality, and is suitable for high-precision welding. Application: Steel, Stainless Steel and Thin Materials.

3)Capacitive Discharge welding supply: A welding method that pre-charging the capacitor and then releasing it to obtain a large current which is suitable for materials with good thermal conductivity, such as aluminum, nickel, and copper. However, the current rises rapidly, the release angle is difficult to control, and spatter is easily generated. Before the next cycle of welding, the capacitor must be allowed to recharge.

4)AC Inverter welding power supplies: It offers excellent thermal efficiency and stability, along with a minimal AC polarity effect, which ensures uniform welding results. Additionally, it is designed for easy upgrades, as it can be integrated with existing AC welding transformers.

5)Transistor-controlled welding power supplies: Offer enhanced precision, faster response, and greater control over the welding process than traditional transformer-based systems. This technology reduces spatter, allows for complex waveforms tailored to various materials, and includes a "check pulse" function to verify workpiece placement before welding, ultimately leading to higher quality and more consistent welds.