ML-6040A

High peak power!

High power density!

High quality fine welding!

▶ Features

◆AMADA MIYACHI’s own-developed high-quality fiber laser oscillator.

◆Fewer heat-affected area.

◆40W average rated power and 80W peak power. Various workpieces from thin stainless steel foils to 100μm or less-thick plates layered can be welded.

◆Suited for small-spot soldering.

◆Φ50μm optical fiber enables high quality fine welding.

◆Efficient fiber laser reduces environmental burden and CO2 emissions. (Power consumption is approximately 60% lesser than that of AMADA MIYACHI’s lamp-pumped laser welder.)

◆Long-life LD reduces maintenance cost.

◆Fully air-cooled model, which is the first in AMADA MIYACHI’s fiber laser welder series, reduces initial costs and running costs.

◆Power feedback feature.

◆Built-in power monitor for better quality control.

◆CDRH certified.

▶ Applications

Electronic components, electric components, machine devices and medical equipment.

▶ Real-time power feedback

The laser output in the lamp-pumped module is monitored in real time. The monitored laser output is compared with the set waveform and power is fed back in real time, varying the energy input to the lamp to reproduce the set waveform and obtain the ideal laser output waveform.

▶ Waveform control

Equipped with a "fixed mode" that features three-level waveforms, and a "flex mode" to provide more complex waveforms.

▶ Power monitor

Laser energy (J) and average power (W) are monitored to detect abnormalities.

▶ Color LCD touch panel

The touch panel can be detached from the main unit and operated by hand.

▶ External communications

Configuration of parameters and monitoring of performance can be carried out from a separate location.

- Type: RS-485 compliant, asynchronous, full duplex

- Data speed: 9600, 19200, 38400 bps

▶ Fade-in/Fade-out

This feature avoids marks at the end of seam welding and provides a beautiful finish even for overlapping circumference seam welding sections.

| Model | ML-6040A | |

|---|---|---|

| Maximum average power | 40 W (Output from oscillator) | |

| Maximum peak power | 80 W (Output from oscillator) (3ms or less of pulse width for40.1 to 80 W) | |

| Pulse width | REPEAT mode | Standard: 0.1 to 500.00 ms (0.1ms steps) |

| Fine setting: 0.05 to 50.00 ms (0.05ms steps) | ||

| CW mode | Standard: 0.1 to 1000.0 s (0.1s steps) | |

| Fine setting: 0.01 to 100.00 s (0.01s steps) | ||

| 1 to 10000 s (1s step) | ||

| Repeated number of pulse / modulation | 1 to 1500 pps | |

| Modulation function | 1 to 1500Hz (Sine wave, triangle wave, square wave) | |

| Oscillation wavelength | 1070 to 1100nm | |

| Safety shutter | With open / close sensor | |

| Positioning guide beam | High-precision condensing LED | |

| Output power stability | ±2%p-p or less@5 W or more | |

| Fiber optic delivery | Up to 2 deliveries of laser output, including powersharing,are available. | |

| No. of programmable schedules | 256 | |

| Measuring and monitoring | Laser energy (J), average power (W) | |

| Counter | Total number of outputs | 9 digits |

| Number of acceptable outputs | 9 digits | |

| Power requirements | Single-phase, 100V to 240V AC (±10%), 50/60 Hz (±3%) (fully auto changeover) | |

| Power consumption | 1.1kW at max. (0.4kW while stand-by) | |

| External communication function | RS-485 | |

| Heat exchange method | Forced air-cooled | |

| Ambient temperature | 0 to 35 °C | |

| Ambient humidity | 20%-80% RH | |

| Dimensions | 416(W) X 725(D) X 717.5(H) | |

| Weight | 72kg | |

*Specifications subject to change without notice.

▶ Dimensions in mm

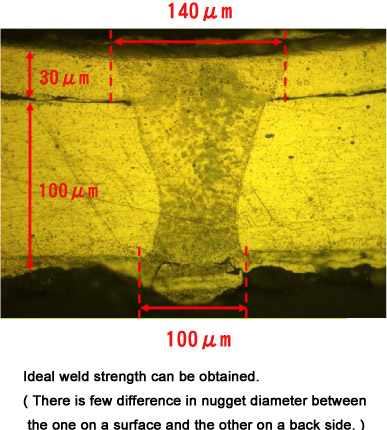

◢ Nuggets on a surface and on a back side (Stainless steel, t=0.03mm×0.1mm)

◢ Cross section of a welded point (Stainless steel, t=0.03mm×0.1mm)