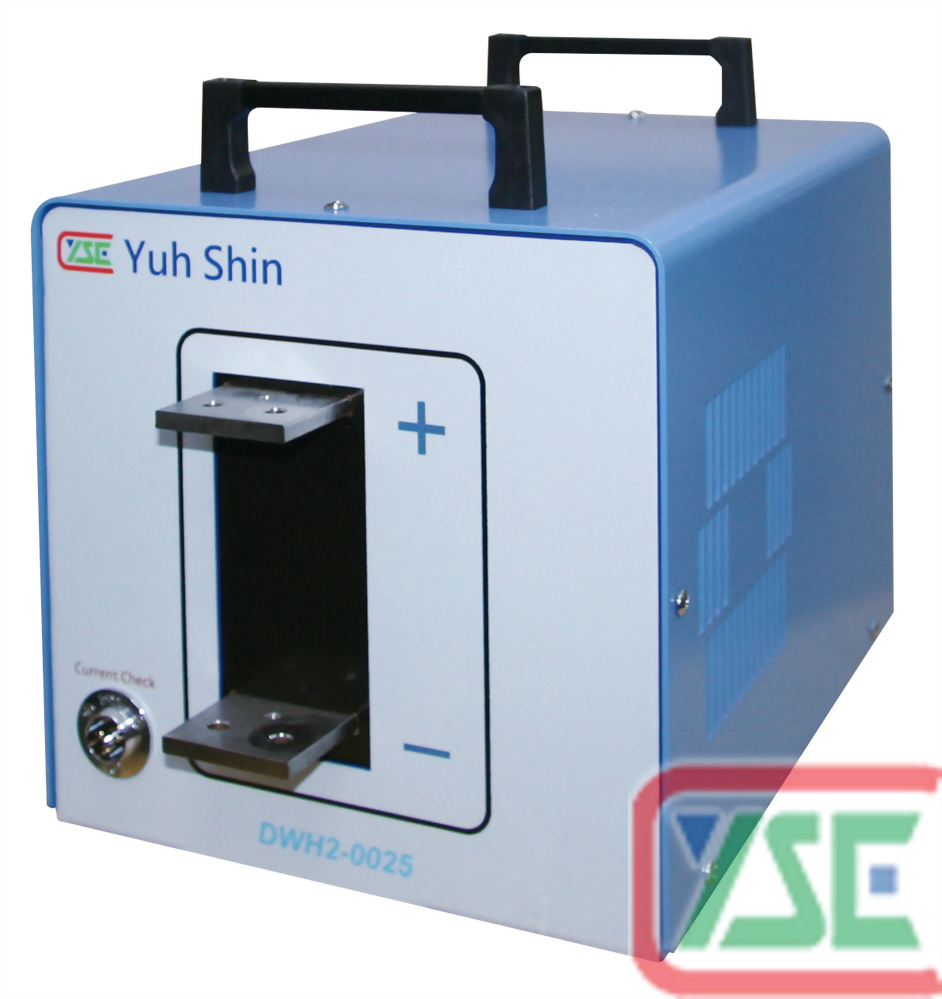

25KVA Benchtop DC Inverter Spot Welding Machine

Equipped with Japanese Brand, TETRA-K INVERTER-Controlled POWER SUPPLY, TH-26VF, TH-50VF, TH-50VFS (Optional), with the positives as below;

1.Inverter frequency changes automatically according to the welding current, thus the ideal direct current can be fed.

2.The second current, second voltage, or second power can be controlled in any desired pattern by software.

3. Settings can be done easily by observing bright display (LCD with back light)

4. 15 welding conditions and various input/output signals are available, considering the possible connection to such as pressurized output and other machinery

5. Good or No

Good judgment can be done by current value monitoring either in the constant

power mode or the constant voltage mode.

6 The Maximum

setting conditions is 9 for 2 welding cycles setting value (Except TH-50VFS)

7.Peak value of

the welding current becomes low, thus splash becomes less.

8.Current control is done with high accuracy and high-speed responded by 16 bits high performance calculation circuit.

9.External setting / Operation / Mode status monitoring or data control can be documented by communication function. (This function is available in optional device RS-232 and RS-422.)

10. Applications: For the small, precise, and consistent resistance welds, includes

- Battery & Energy Storage: Welding lithium-ion battery tabs, Battery pack assembly

- Electronics & Electrical Components: Welding terminals, leads, and connectors, Relay and switch contact welding, Sensor and fuse assembly

- Automotive & Transportation (Small Parts): Wire harness terminals, Small brackets and clips, actuator components

- Metal Fabrication & Hardware: Stainless steel and low-carbon steel sheet joining, Small enclosures, clips, and fasteners

- Home Appliance Components: Thermostat contacts, Heating element terminals, Motor laminations and small frames

1.KVA Ratings: 8KVA, 17KVA & 25KVA

2.Input: 220V / 380V

3.Benchtop Type

4.Pneumatic Control System

1. Custom-Built models are welcome, simply send us the workpiece specification and welding requirement. Our engineers are available to work with you to customize welders that meet your specific application requirements.

2. Specifications are subject to change without prior notice due to constant improvements.